Helical Cathode Electro Advanced Oxidation Process (HCEAOP)

The Process you can TRUST

Helical Cathode Electro Advanced Oxidation

Customer Summary

The client process a large number of eggs daily and other products.

Main Highlights

- Low power Consumption

- Elimination of all chemicals, except Polymer.

- Long life Anode consumption (800 hours)

- Reduce the amount of sludge production by 80 or 90 % compared to chemical treatment.

- Small Foot Print.

- With Electrocoagulation Technology the cost per litre decreases as the flow rate increases. With Chemical treatment the cost per litre increase as the flow rate increases.

Problem

Weekly water processing volume 200 KiloLitres. Using chemical coagulation at 80 GPM chemical treatment was becoming cost prohibited. spending over 700,000 $ in chemical and generating a very large number of sludge. The foul odour in the plant from the chemical process was so bad neighbors complained.

Solution

- H2Electrofloc reduced the treatment processing cost by 20%

- Reduce sludge production by 90%.

- Eliminated the foul odour in the plant.

Customer Summary

Carter Day Industries (Winnipeg Manitoba)

Re: Hardening Plant using Cyanide Bath to harden steel

Main Highlights

- Total Cyanide Destruction below 1 ppm.

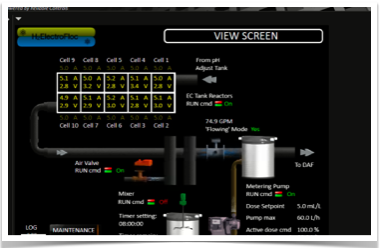

- Fully Automated operation.

- Small Full print.

- System was tailored designed.

Problem

City bylaw in 2011 changed allowable Total Cyanide discharge from 10 ppm down to 2 ppm.

Solution

Cyanide destruction processing plant was installed in 2012 with Electrocoagulation. Plant is still operational today producing total cyanide discharge levels of 0.5 ppm.

The Electro-coagulation process allow the customer to continue operations in Winnipeg under the new bylaw city requirements.

Customer Summary

Newfoundland Aqua Services Ltd. (St Albans, NF Labrador)

Re: Fishnet Repair Factory

Main Highlights

- Water from Parts-washers contain a very high level of solids

- 260 GPM system, Tailored designed to handle the daily operational flow.

- Customer was able to recycle the water good for cleaning rather than using evaporation.

Problem

Fishnets used for fish farming contains a Copper Special Paint to prevent fouling. Government does not allow to clean the fishnets in the ocean. The cleaning of this large expensive nets has to be done on land. This create the challenge that copper discharge has to meet local regulations for discharge

Solution

Client was not treating the water but rather concentrating the contaminants and then evaporating the water.

We put an Electrocoagulation treatment system followed by a DAF.